- Home

- Products

- Corrugated Board-Grinding stones

- Corrugated Board-Razor Slitter Knife

- Tissue converting grinder and Knives

- Cutting Knives

- Diamond Grinding Wheels

- CBN Grinding Wheels

- Diamond/Cbn Brazed Grinding Wheels

- Bond of Grinding Wheel

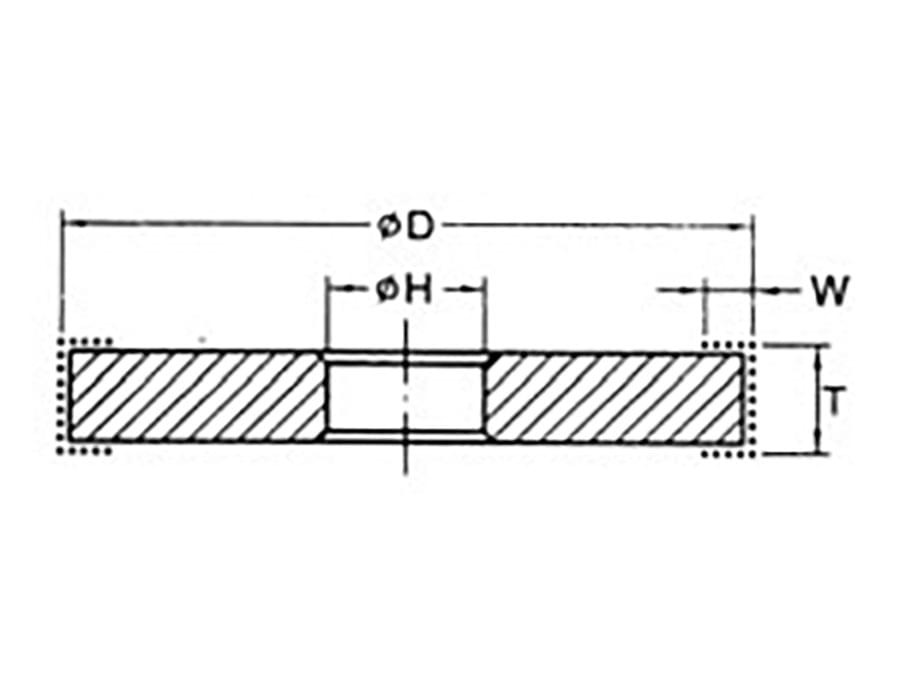

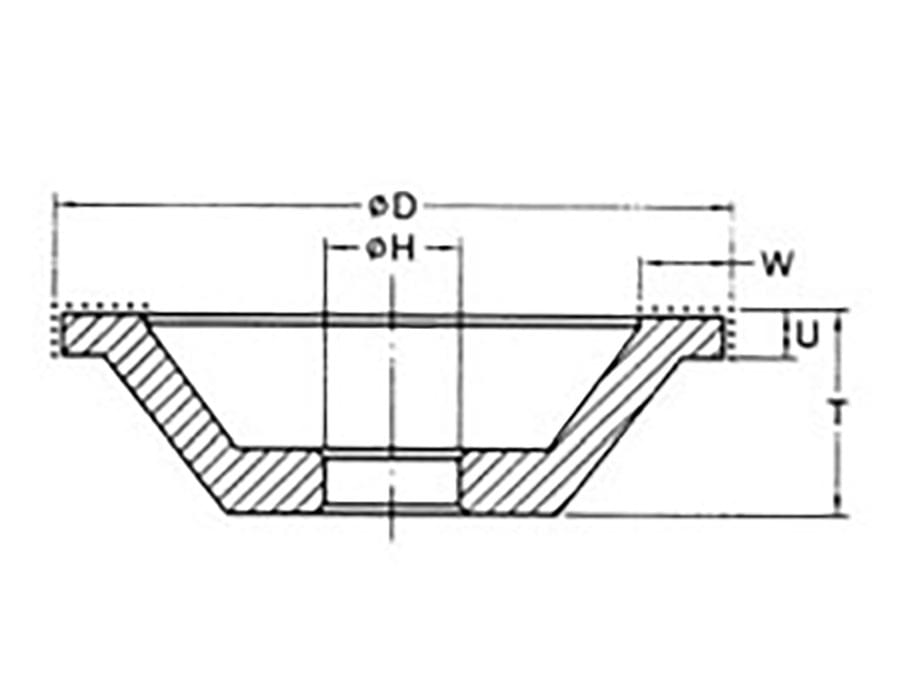

- Shape of Grinding Wheels

- CNC Tools Grinding Wheels

- Conventional Grinding Wheels

- Spare Parts Supply

- Custom CNC Machining Services

- Technique Support

- About us

- FAQ

- Contact us

- Home

- Products

- Bond of Grinding Wheel

- Electroplate Grinding Wheels

Electroplate Grinding Wheels

Electroplated grinding wheels is an excellent option when an aggressive amount of stock removal is required.

A single, uniform layer of diamond or CBN crystal is electroplated to a precision machined steel surface.

How to Produce Electroplated Diamond Grinding Wheels or Electroplated CBN Grinding Wheels?

The electroplated diamond wheel is a diamond grinding wheel made by electrochemical method. The working layer of the grinding wheel contains diamond abrasive grains, and the diamond abrasive is bonded to the substrate by a metal bonding agent. First, the thickness of the deposited metal bond is 20% of the height of the diamond abrasive grains (upper sand), and then the diamond abrasive grains are continuously bonded (thickened) with a metal bond to a thickness of about 2/3 of the height of the abrasive grains. Includes diamond dressing wheels, diamond wheels for grinding or cutting

The electroplating process gives the most aggressive, open structure of all bonding methods. This bond type is primarily used in from grinding applications. All bonds can be fashioned into any standard or custom shape.

The Advantages of Electroplated Diamond Wheelsor Electroplated CBN Wheels:

Aggressive/free cutting bond structure adapts to various spindle speeds. Ability to grind a particular shape or profile.Increased productivity. Improved grind ratios. The usage of Electroplated Diamond Grinding Wheels; Tungsten Carbide; Ceramic or Aluminum Oxide. The Usage of Electroplated CBN Grinding Wheel for High-Speed Steel amd Hardened Steel.

LATEST POST

- Convoluted Grinding Wheels 10-23-2024

- Diamond dressing tools 09-11-2024

- Customize 6A2 Type Diamond Grinding Whees 07-31-2024

HOT TOPIC

CONTACT US

-

SHANGCHENG CTOOLMAKE CO., LTD

-

TaiBai North Road No.1, BeiLin Distict, XiAn City, Shannxi, China